Produktangebot

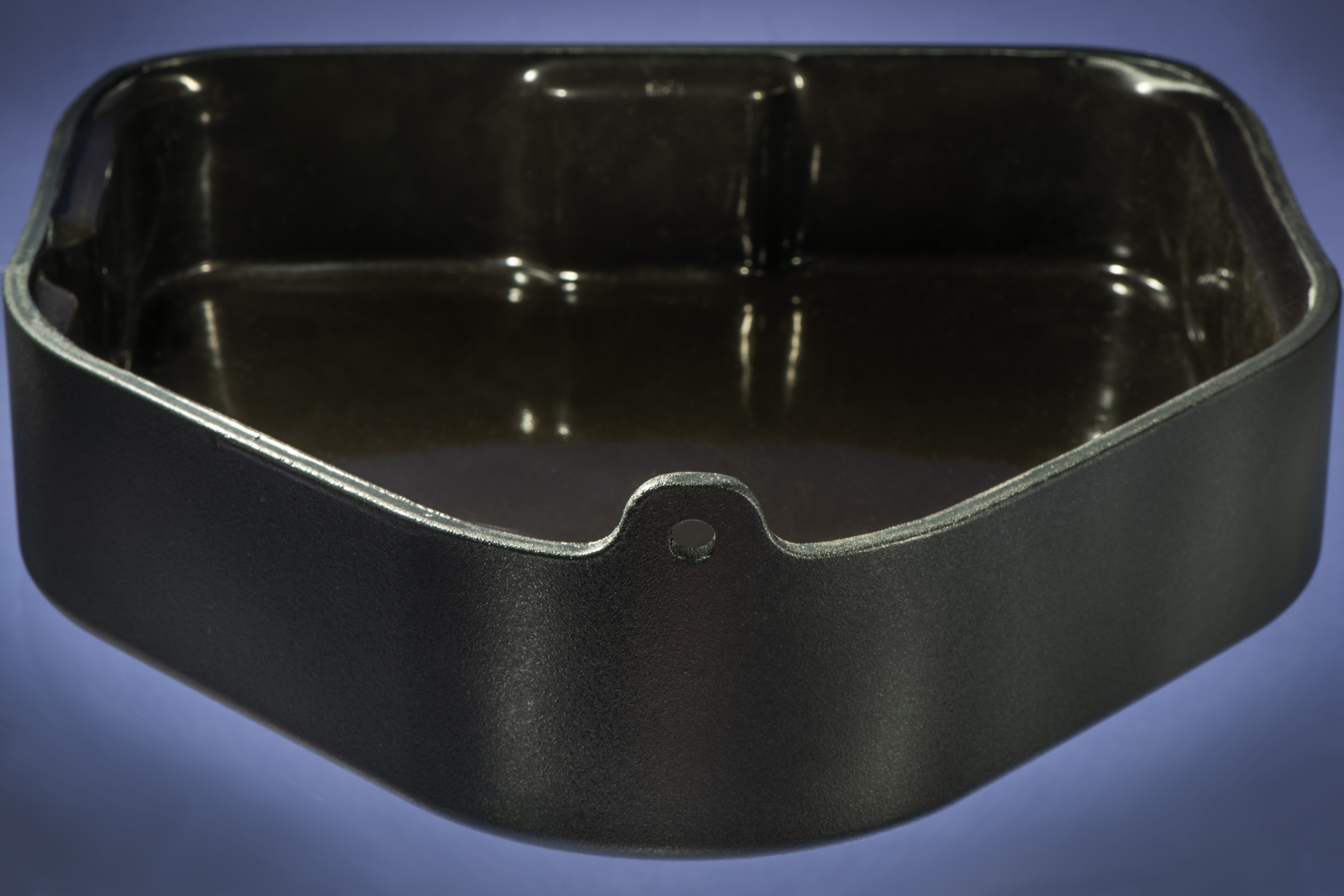

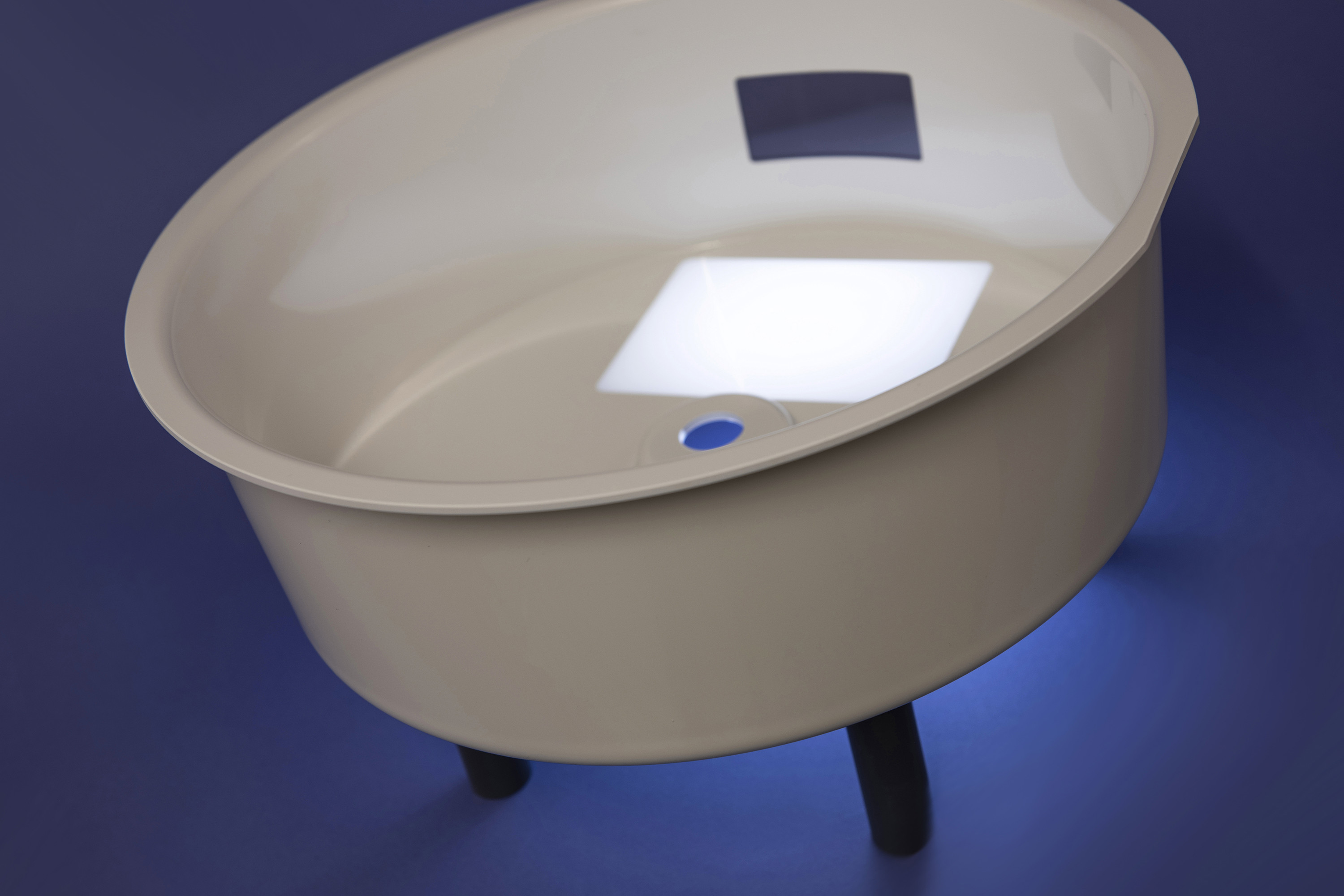

Tiefziehteile

Einführung

Beim Tiefziehen werden thermoplastische Platten oder Folien zu dreidimensionalen Fertigteilen geformt. Die Umformung der Kunststoff-Halbzeuge findet unter Einsatz von Wärme, Druckluft und Vakuum in Metall- oder Holzformen statt. Für dieses Verfahren sprechen die relativ niedrigen Formkosten, welche auch für die wirtschaftliche Herstellung von kleineren Serien spricht.

Anwendungsgebiete

- Apparatebau

- Anlagenbau

- Maschinenbau

- Baumaschinen

- Nutzfahrzeuge

Beispiele für Fertigteile im Tiefziehverfahren

- Behälter

- Abdeckungen

- Gehäuse

- Hauben

Es sind Formgrössen bis 4'200 x 2'500 mm realisierbar. Zur Nachbearbeitung steht ein grosses Spektrum an modernsten CNC-Bearbeitungszentren zur Verfügung.

Unser Angebot

Wir bieten Ihnen individuellen Lösungen von Tiefziehteilen mit einem breiten Werkstoffsortiment zu günstigen Konditionen an.