Product range

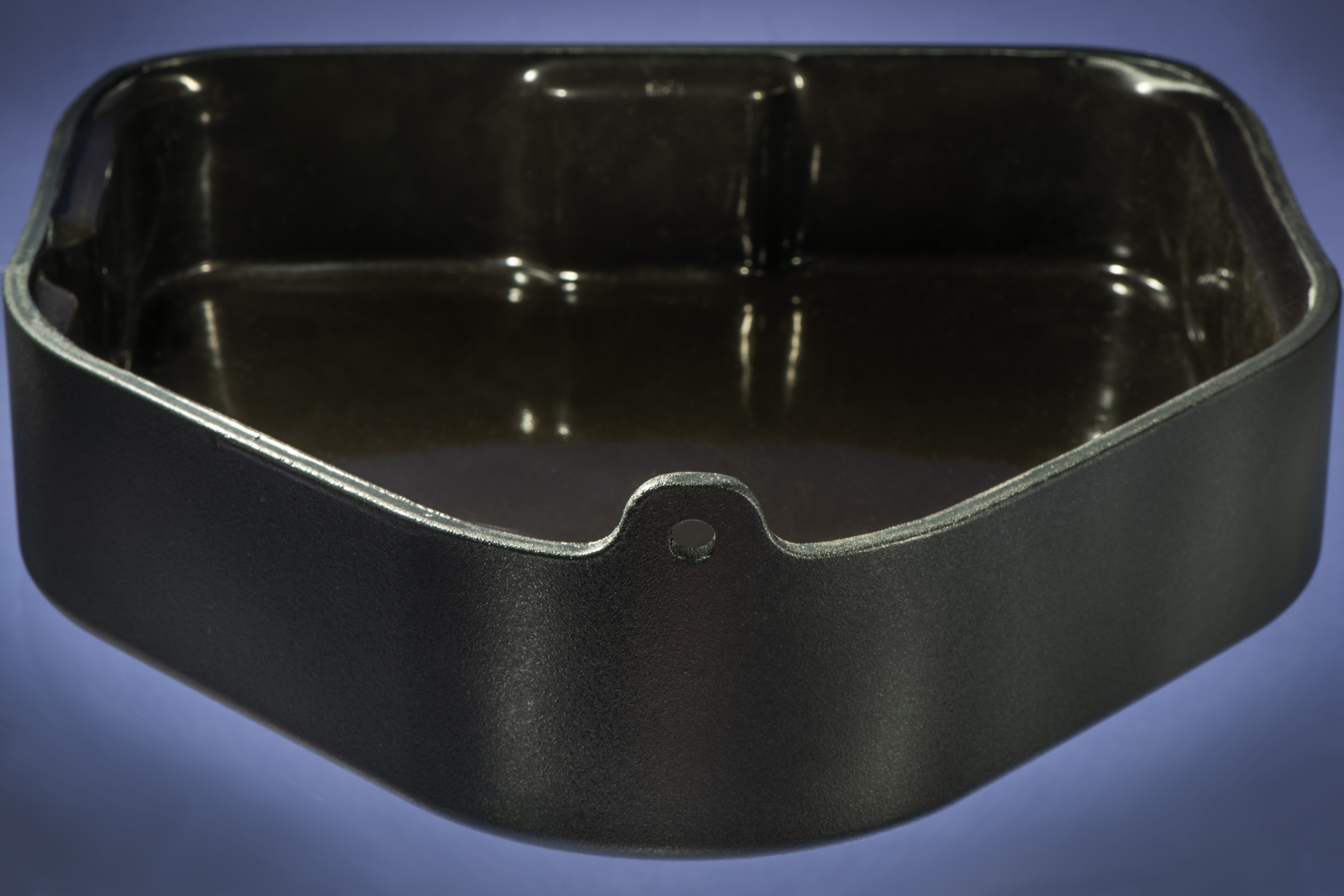

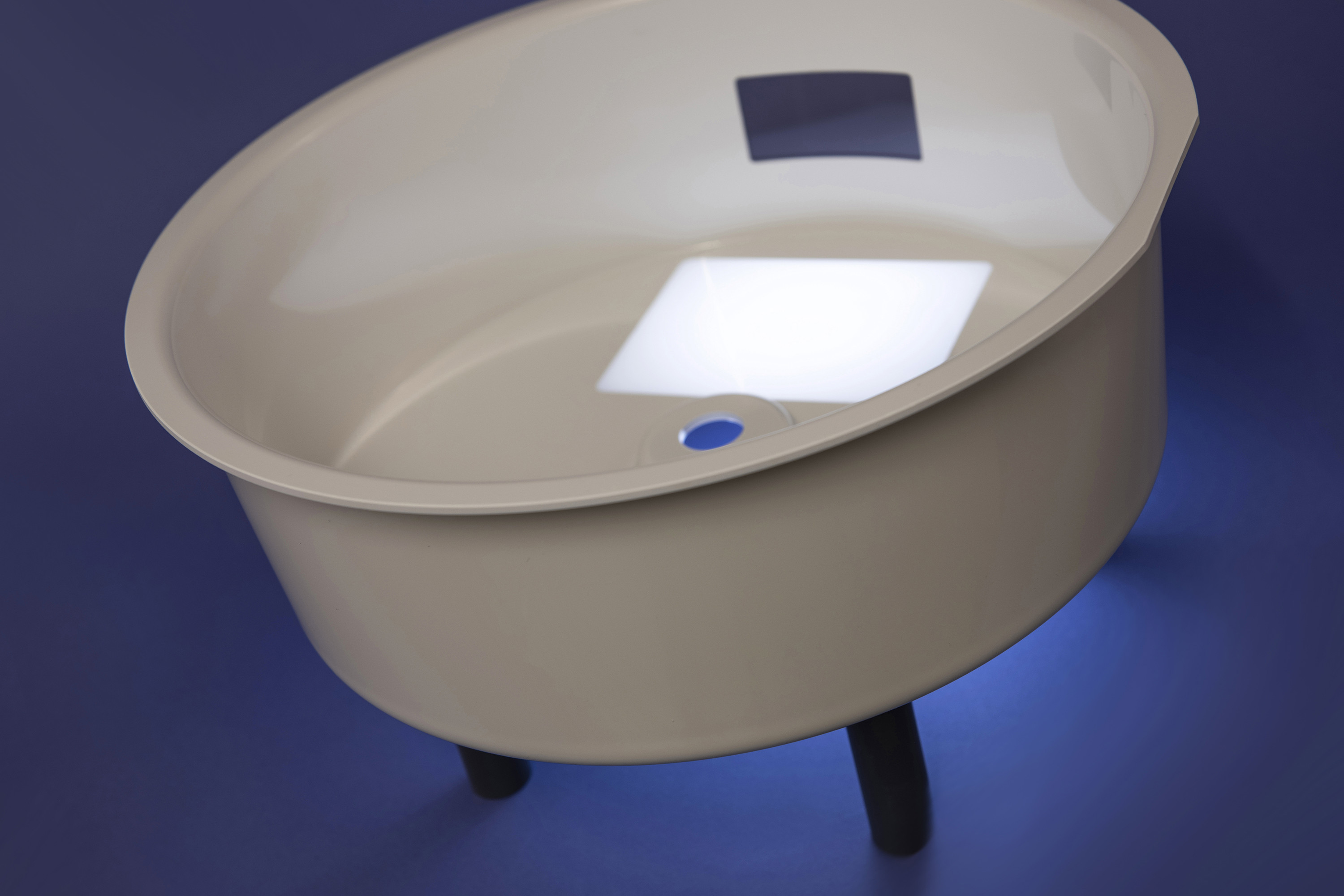

Thermoformed parts

Introduction

Thermoforming involves moulding thermoplastic sheets or films into three-dimensional finished parts. The semi-finished plastic products are formed in metal or wooden moulds using heat, compressed air and vacuum. The relatively low moulding costs speak in favour of this process, which also speaks for the economical production of smaller series.

Application areas

- Apparatus engineering

- Plant construction

- Mechanical engineering

- Construction machinery

- Commercial vehicles

Examples of finished parts using the thermoforming process

- Containers

- Covers

- Housing

- Hoods

Mould sizes up to 4,200 x 2,500 mm are possible. We have a wide range of the latest CNC processing centres for the reworking and finishing phase.

Our offer

We offer our customers individual solutions for thermoformed parts with a wide range of materials at competitive rates.