Production

The targeted focus on the processing of plastics makes KUNDERT the ideal manufacturing partner in the following production areas.

The targeted focus on the processing of plastics makes KUNDERT the ideal manufacturing partner in the following production areas.

Thanks to state-of-the-art production facilities and a wide range of materials, KUNDERT can manufacture customised plastic parts that are optimally tailored to your needs.

In our plastic injection moulding shop, all thermoplastics can be processed into complex components on state-of-the-art equipment. KUNDERT is perfectly equipped to offer customised solutions.

KUNDERT is the leading Swiss manufacturer of semi-finished and finished polyurethane parts. Thanks to state-of-the-art polyurethane processing systems and a wide range of materials, KUNDERT is able to offer customised solutions. KUNDERT is constantly developing new materials which can be tested in its own test laboratory.

As one of the most diverse and largest suppliers of semi-finished plastic products in Switzerland, KUNDERT has over 180 different types of plastic in over 5000 dimensions. The modern high-bay warehouse offers space for 700 tonnes in over 2000 storage compartments. The extensive cutting service allows us to supply you with the products you require within 24 hours, subject to stock availability.

In addition to the production of finished plastic parts and moulded parts made of polyurethane, KUNDERT also offers the assembly of complete subassemblies. By purchasing complete assemblies, you can rationalise your production processes even further.

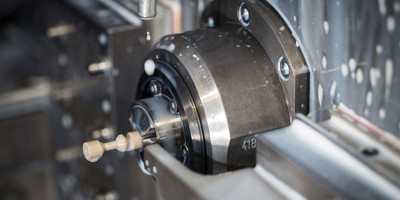

Injection and polyurethane moulds are the decisive factor for high-quality plastic and polyurethane parts. Experience and in-depth knowledge of injection moulding, polyurethane casting and tool and mould making are the prerequisites for the optimum design of moulded parts and tools. In-house toolmaking, modern production techniques and qualified and experienced employees are the key to quality, efficiency and speed.