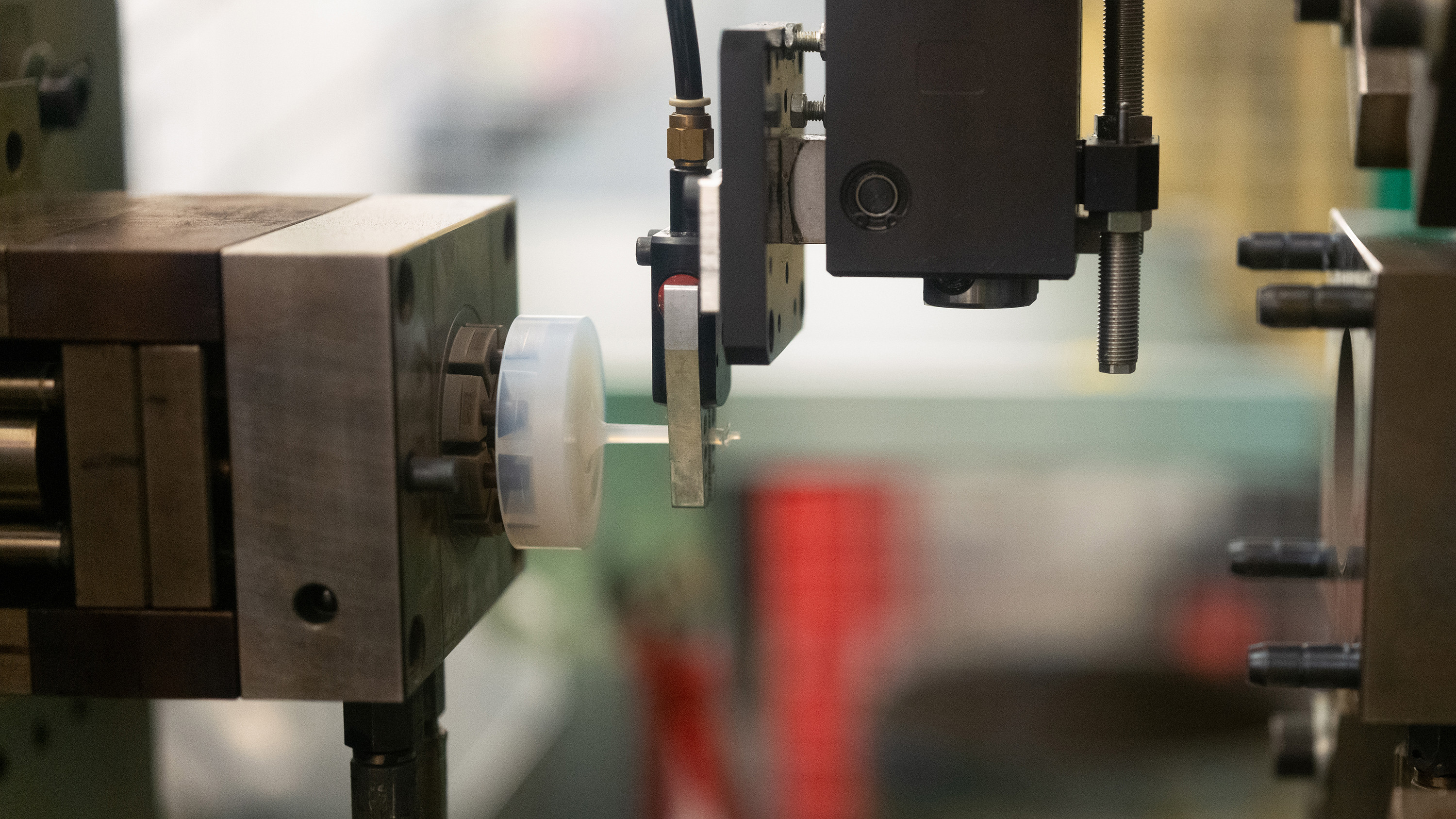

Production

Injection moulding

Introduction

In our plastic injection moulding shop, all thermoplastics can be processed into complex components on state-of-the-art equipment. KUNDERT is perfectly equipped to offer customised solutions.

Range of parts

- Processing of all unfilled and reinforced thermoplastics

- Specialised in PEEK, LCP, PPS, PSU, PPA (PA HT) and fluoropolymers (e.g. Teflon PFA, PTFE, PVDF)

- Customised compounds and colours

- Overmoulding of inserts (e.g. steel, glass, brass, plastic)

- Quantities from 200 to 10 million per year

Production facilities

- 13 injection moulding machines with clamping forces from 180 to 1100 kN

- Post-processing methods such as printing, painting, ultrasonic welding and mechanical reworking

- Assembly of complete components