Production

Machining

Introduction

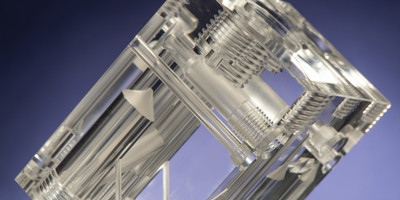

Thanks to state-of-the-art production facilities and a wide range of materials, KUNDERT can manufacture customised plastic parts that are optimally tailored to your needs.

Range of components

- Prototypes, small and large batches

- Whole range from small precision components to large-scale machine components

- Simple and complex turned / milled parts (short and long turning, 5-axis simultaneous)

- Just-in-time production through automated production systems

- Mechanically reworked blanks (PUR, injection molding)

Manufacturing possibilities

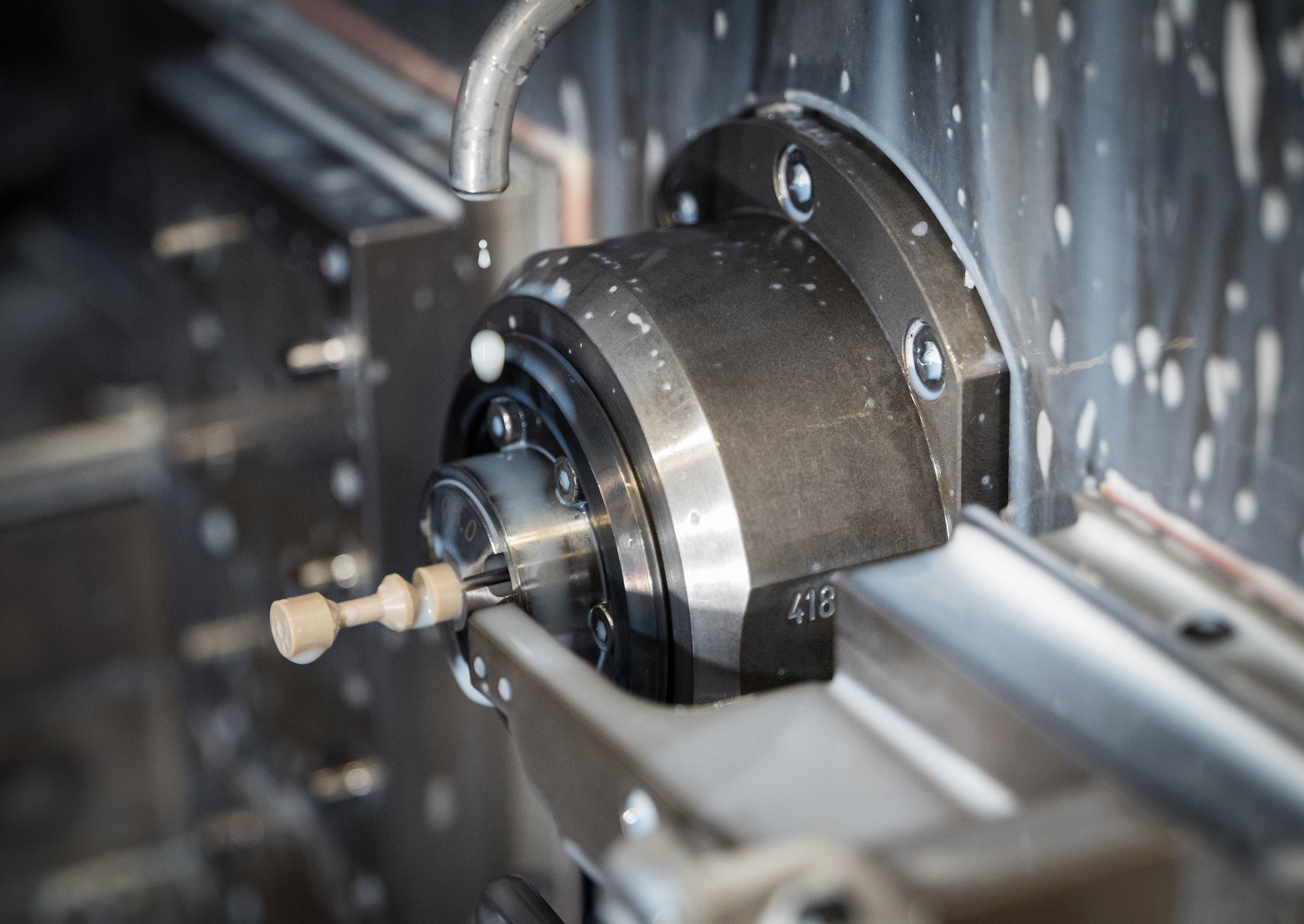

The production department for machining comprises around 40 machines, including over 20 CNC machining centres and 50 employees.

Milling

- 6-axis high-speed machining centres for large area parts and complex geometries

- 5-axis machining centres for complex parts

- 4-axis machining centres for larger runs

- 3-axis milling machines for simpler parts

Turning

- CNC turning centres with up to 5 controlled axis and counter spindles from rod or feed

- CNC sliding headstock lathes with up to 10 controlled axis, wet and dry machining

- CNC universal lathe for large turned parts