UK-VUL 65A to 95A (Vulkollan®)

Vulkollan® - made from Desmodur® 15 - is one of the highest performing elastomers on the market and combines maximum mechanical strength with maximum dynamic load-bearing capacity. For this reason, Vulkollan® is used in many technical areas with the highest requirements. KUNDERT uses the material designation UK-VUL 65 to 95A.

KUNDERT is a licensed processor and brand contract partner of Covestro. This ensures that the Vulkollan® products comply with Covestro's processing guidelines at all times.

Solid Vulkollan® is produced in a multi-stage process developed by Covestro through chemical reactions between the high-quality Vulkollan® polyester polyols, Desmodur® 15 and glycols. Desmodur® 15 is the trade name for naphthalene 1,5-diisocyanate (NDI) from Covestro.

Properties of UK-VUL 65 to 95A

- Hardness range from approx. 65 ShA to 95 ShA

- Dynamically highly resilient

- Excellent mechanical wear resistance

- High impact resilience, even with hard settings

- Excellent tear and tear propagation resistance

- Low compression set

- Can be used between -35°C and +80°C (also up to +120°C for short periods)

- Good resistance to mineral oils, greases, petrol and various solvents

- Good resistance to ozone, UV and high-energy radiation

The high mechanical and dynamic resilience and deformation resistance of Vulkollan® should be particularly emphasised.

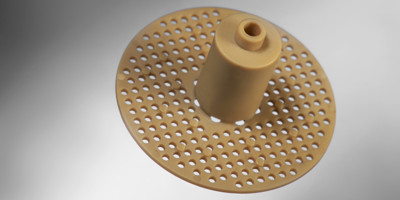

Application examples for UK-VUL 65 to 95A

- Roller and cylinder linings

- Damping and suspension parts

- Linings as wear and noise protection

- Drive and coupling elements

- Seals

- Wipers

Thanks to its outstanding property profile, UK-VUL 65 to 95A has conquered many technical areas of application. Moulded parts or coatings are used in all areas of application where particularly high wear resistance and high mechanical strength are required.

You can find the data sheet for UK-VUL 65A to 95A here.

Vulkollan®/Desmodur® are registered trademarks of the Covestro Group.